When recording sound from several orchestral instruments being played by different musicians using a single microphone, the only way to adjust the sound balance is to change the position of the musicians relative to the microphone. When recording direct to stereo master tape, it’s crucial to make sure that all the voices and instruments sound right before you hit the record button. Presented here is an eight-input audio mixer circuit with bass, treble, volume and balance controls, which you can use to balance sounds from all the sources until you have the desired mix. For capturing the sound from various sources, the audio mixer employs up to eight microphones.

When recording sound from several orchestral instruments being played by different musicians using a single microphone, the only way to adjust the sound balance is to change the position of the musicians relative to the microphone. When recording direct to stereo master tape, it’s crucial to make sure that all the voices and instruments sound right before you hit the record button. Presented here is an eight-input audio mixer circuit with bass, treble, volume and balance controls, which you can use to balance sounds from all the sources until you have the desired mix. For capturing the sound from various sources, the audio mixer employs up to eight microphones.

Audio mixer circuit

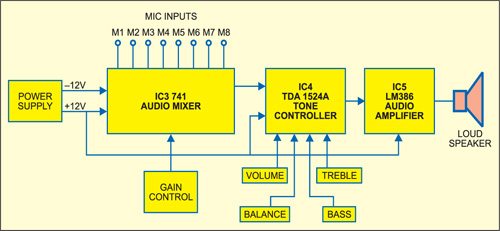

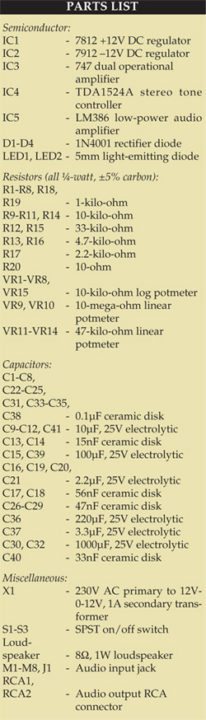

Fig. 1 shows the block diagram of the audio mixing system along with the audio power amplifier, while the circuit of the audio mixer along with tone controller is shown in Fig. 2. The power supply and audio power amplifier circuits are shown in Figs 3 and 4, respectively.

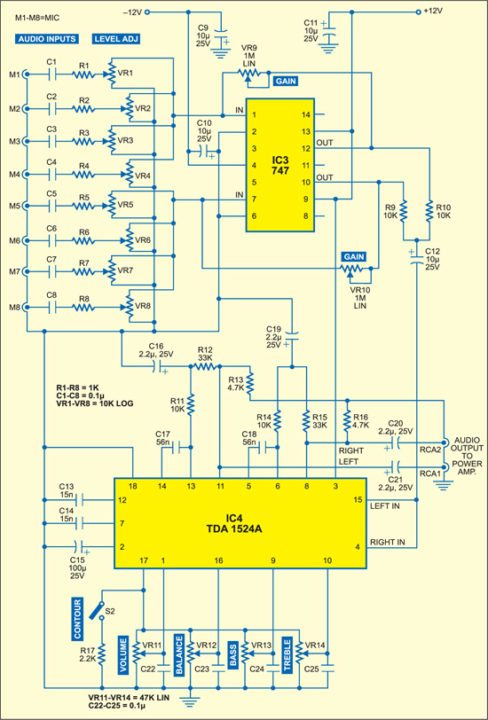

Here, dual operational amplifier IC 747 (IC3) is used for mixing several inputs without any mutual interaction. The two internal amplifiers share a common bias network and power supply. The IC has short-circuit protection and wide common-mode and differential voltage ranges.

In this application, +12V and –12V regulated DC supplies are used for operation of IC 747. The microphone output signals M1 through M4, after their individual level adjustments, are mixed and applied across the differential input terminals (pins 1 and 2). Similarly, microphone outputs M5 through M8 are applied across the differential input terminals (pins 7 and 6) of the second amplifier inside op-amp IC 747 after their individual level adjustments.

Circuit operation

For level adjustment, logarithmic variable resistors VR1 through VR4 and VR5 through VR8, respectively, are employed while feeding the output from respective microphones to the input of the two amplifiers inside IC 747. The outputs of the two amplifiers taken from pins 12 and 10, respectively, are combined at the junction of resistors R9 and R10 before feeding to the next stage (tone controller) via capacitor C12 (10 µF). The overall gain of individual amplifiers can be adjusted with the help of potmeters VR9 and VR10, respectively.

The amplified mixed signal output of IC 747 is applied to shorted input pins 15 and 4 of stereo tone controller IC TDA1524A (IC4). TDA1524A is designed as an active stereo-tone/volume control for car radios, TV receivers and mains-fed equipment. It includes functions for bass and treble control, volume control with built-in contour (can be switched off) and balance. All these functions can be controlled by DC voltages or by single linear potentiometers. This IC serves as an efficient tone controller. Although it may work reasonably well with 9V DC supply, for better bass response, a 12V supply can be used. A good heat-sink is necessary for longer life and better performance of the IC.

Features of TDA1524A are:

1. Simple construction

2. Low noise and distortion

3. Switchable contour (for quick changing of the tonal response)

4. Its output can drive most power amplifiers.

5. Bass emphasis can be increased by incorporating a double-pole, low-pass filter

6. Wide power supply voltage range

General specifications are:

1. DC input: 12V (typical)

2. DC battery: 35 mA

3. Maximum output: 3V RMS

4. Maximum input: 2.5V

5. Maximum gain: 21.5 dB

6. Volume control range: –80 to+121.5 dB

7. THD at 1 kHz: 0.3%

8. Ripple rejection at 100 Hz: 50 dB

Potmeters VR11, VR12, VR13 and VR14 are meant for adjustment of volume, balance, bass and treble, respectively. Switch S2 is contour switch, which can be used to change the tonal response of the of the IC. The outputs are available at pins 8 and 11 for right and left channel, respectively. (EFY note. Since both the left- and right-channel input pins 15 and 4 have been shorted in this application, the IC acts as a mono volume/tone control circuit.)

Audio power amplifier

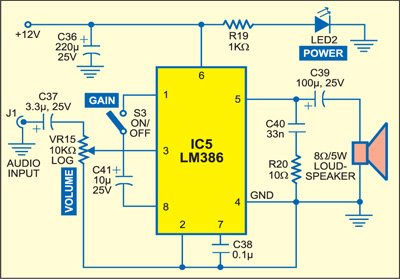

The audio amplifier circuit shown in Fig. 4 is optional. One can use much higher-power audio amplifier along with the audio mixer circuit.

The low-power audio amplifier employing IC LM386 (IC5) shown in Fig. 4 can output a maximum audio power of 1 watt. It gets +12V DC supply at its pin 6. The audio input from sources like Walkman and audio mixer can be fed to pin 3 of IC5 through volume control VR15.

The gain of LM386 is internally set to 20 to keep the external part count low. However, to make LM386 a more versatile amplifier, pins 1 and 8 are provided for setting the gain—externally to any value between 20 and 200—by using an appropriate combination of a resistor and a capacitor. If only a capacitor is put between pins 1 and 8 using switch S3 as shown in Fig. 4, the gain would increase to 200 (46 dB). The amplified output is taken from pin 5 and fed to the loudspeaker through electrolytic capacitor C39 (100 µF). The higher the value of C39, the higher the pitch of the audio frequency response in the speaker.

Power supply. The power supply section for the circuit is shown in Fig. 3. It consists of a step-down transformer (230V AC primary to 12V-0-12V, 1A secondary), bridge rectifier, filter network and regulator ICs 7812 and 7912 to provide +12V and –12V regulated DC outputs, respectively. When switch S1 is closed, the presence of power is indicated by the glowing of LED1.

Construction

Assemble the circuit on any general-purpose PCB. Mount IC bases on the PCB. There is no soldering method that is ideal for all IC packages. The use of IC bases prevents damage to the ICs while soldering and also makes it easy to replace them. Use audio input jack connectors for M1 through M8 input points. Also use audio output connectors at the outputs of IC4.

Download PCB and component layout PDFs: click here

A combined actual-size, single-side PCB layout for Figs 2 and 3 is shown in Fig. 5 and its components layout in Fig. 6. The solder-side PCB layout for Fig. 4 is shown in Fig. 7 and its components layout in Fig. 8.

Note. If you are not using IC base for TDA1524A, the maximum permissible temperature of the solder is 260°C; solder at this temperature must not be in contact with the joint for more than five seconds. The total contact time of successive solder waves must not exceed five seconds while using wave soldering.

Testing procedure

- After assembling the PCB, check the circuit connections before switching on the power supply.

- Use a standard microphone at the first input point M1 and then keep it near an audio source. You can use the power amplifier circuit given here for testing or another higher-output power amplifier.

- Vary VR1 slowly until a clear and distortion-free amplified output is obtained.

- If the sound output is not clear and VR1 does not help, vary gain control VR9.

- If the problem still persists, check volume, balance, bass and treble controls.

- Check the various controls in your audio power amplifier section.

- Repeat steps 2 through 5 for the rest of the inputs. Having checked all the inputs, now the audio mixer is ready for use.

Feel interested? Check out more circuit projects.

The post Audio Mixer with Multiple Controls appeared first on Electronics For You.

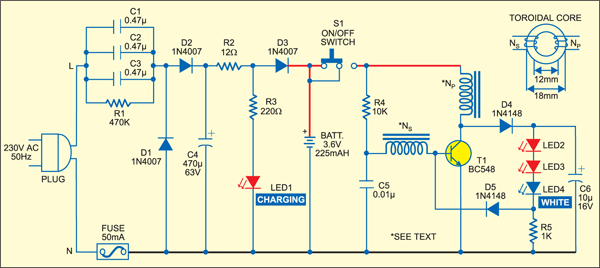

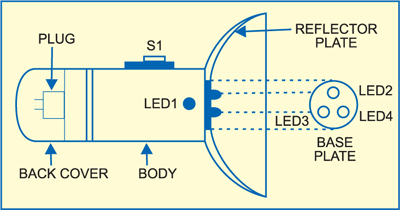

Rechargeable torches don’t come without problems. You need to replace the bulbs and charge the batteries frequently. The average incandescent light-emitting diode (LED) based torch, for instance, consumes around 2 watts. Here’s a white LED based rechargeable torch that consumes just 300 mW and has 60 per cent longer service life than an average incandescent torch.

Rechargeable torches don’t come without problems. You need to replace the bulbs and charge the batteries frequently. The average incandescent light-emitting diode (LED) based torch, for instance, consumes around 2 watts. Here’s a white LED based rechargeable torch that consumes just 300 mW and has 60 per cent longer service life than an average incandescent torch.

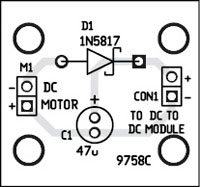

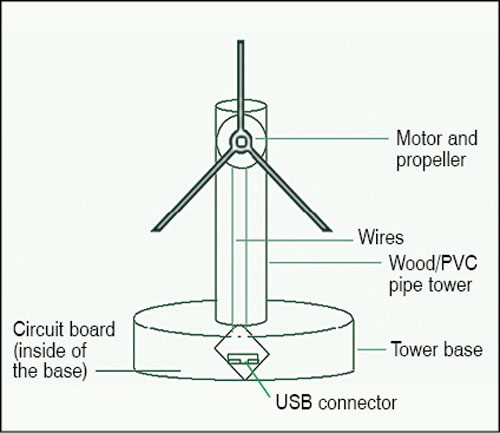

As shown in Fig. 4, the circuit is built around a DC motor,

As shown in Fig. 4, the circuit is built around a DC motor,

Most of the accidents on highways during night occur due to drivers’ poor vision caused by the continuous exposure of their eyes to the bright light from the headlamps of approaching vehicles. The poor vision is due to exhaustion of the visual pigment in the eyes, which induces sleep to restore the pigment. This anti-sleep alarm keeps you awake.

Most of the accidents on highways during night occur due to drivers’ poor vision caused by the continuous exposure of their eyes to the bright light from the headlamps of approaching vehicles. The poor vision is due to exhaustion of the visual pigment in the eyes, which induces sleep to restore the pigment. This anti-sleep alarm keeps you awake.

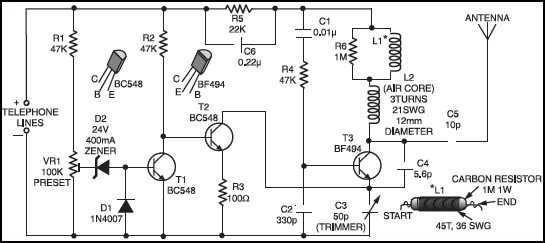

Here is a simple yet very useful phone broadcaster circuit which can be used to eavesdrop on a telephone conversation. The circuit can also be used as a wireless telephone amplifier.

Here is a simple yet very useful phone broadcaster circuit which can be used to eavesdrop on a telephone conversation. The circuit can also be used as a wireless telephone amplifier.