This mobile sniffer circuit can detect the use of a GSM mobile in mobile-phone-restricted areas such as examination halls and other ‘do not disturb’ areas. It can detect the activity of the phone from a distance of eight metres or more. The sniffer keeps monitoring the RF level in the area and gives warning indication if the RF level increases due to mobile phone activity. If two identical units of this sniffer are placed in the room, the range can be extended to a radius of 15-16 metres. The circuit can detect all forms of mobile phone activity even in the silent mode.

This mobile sniffer circuit can detect the use of a GSM mobile in mobile-phone-restricted areas such as examination halls and other ‘do not disturb’ areas. It can detect the activity of the phone from a distance of eight metres or more. The sniffer keeps monitoring the RF level in the area and gives warning indication if the RF level increases due to mobile phone activity. If two identical units of this sniffer are placed in the room, the range can be extended to a radius of 15-16 metres. The circuit can detect all forms of mobile phone activity even in the silent mode.

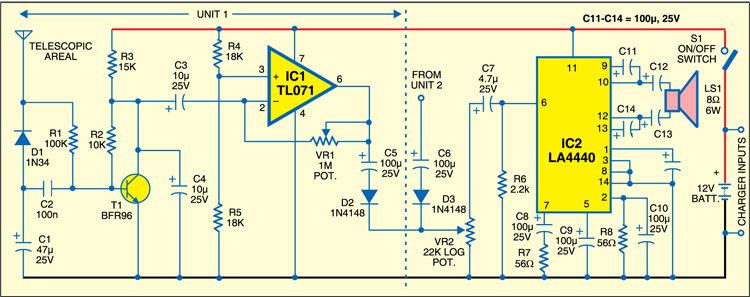

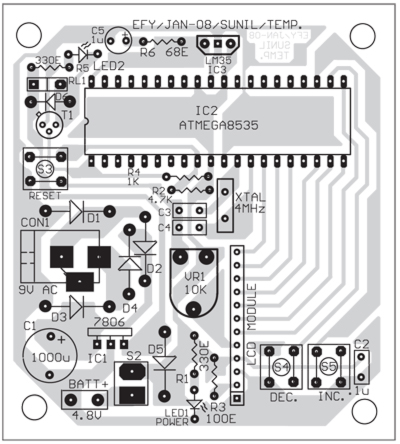

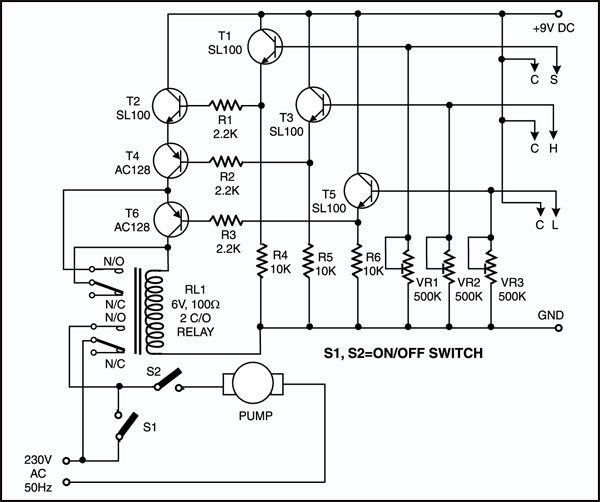

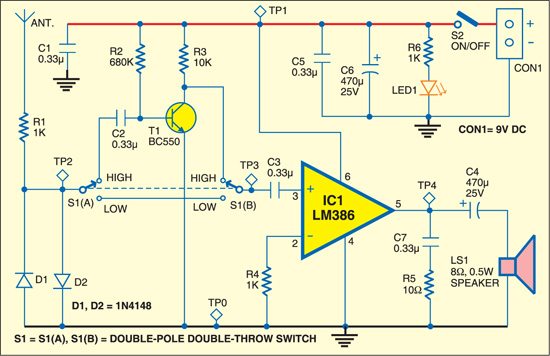

Circuit diagram for the mobile sniffer

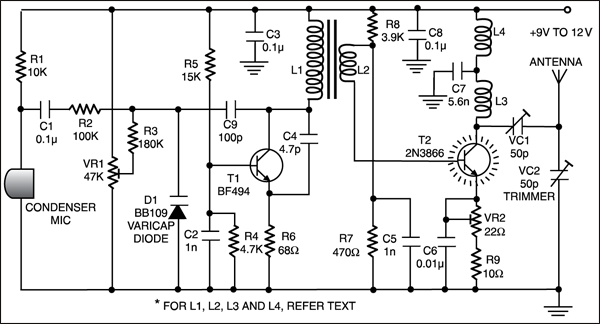

The mobile sniffer circuit is designed as a sensitive RF detector. RF signal diode 1N34 forms the major element. Along with resistor R1 and capacitor C2, the diode picks up RF energy in the area. In the standby mode, the output from the diode is around 0.6 millivolt, which rises to 60 millivolts when it receives the high energy radiation from the mobile phone. Since the voltage level from the sensor diode is too weak, three-stage amplification is provided to give the warning indication through the speaker.

Circuit working

Output pulses from the sensor diode (1N34) are preamplified by transistor BFR96 (T1). It is an RF/microwave low power transistor with high current gain and bandwidth. It has a high power gain of 14.5 dB at 0.5 GHz. Resistor R2 maintains the feedback and capacitor C4 keeps the collector voltage of T1 steady for maintaining the amplification.

The preamplified signals are fed to the second amplifier stage built around IC TL071 (IC1). It is a low-noise, JFET-input op-amp with low input bias and offset current. The BiFET technology provides fast slew rates to IC1. Here IC1 is designed as an inverting amplifier with resistor combination of R4 and R5 as potential divider to set half sup-ply voltage to its non-inverting input. The inverting input of IC1 receives the preamplified signals from T1. Variable resistor VR1 adjusts the feedback of the inverting amplifier and hence its gain.

The amplified signals from IC1 pass through capacitor C5 and diode D2 into volume control VR2. It also receives the signals from unit 2 identical to unit 1 through capacitor C6 and diode D3. From volume control VR2, power amplifier IC2 gets the amplified signals. IC LA4440 (IC2) is a two-channel audio power amplifier with inbuilt dual channels for stereo and bridge amplifier applications. In dual mode it gives 6W, and in bridge mode the output is 19W. It has good ripple rejection of 46 dB, small residual noise, built-in over-voltage and surge-voltage protection, and pin-to-pin protection. Here IC2 is wired in bridge configuration using only one input.

Is the circuit working?

Normally, a feeble hissing noise is heard from the speaker, indicating that the sniffer is active. The hissing noise is due to the detection of RF in the area. Its loudness can be adjusted using VR2. When a mobile phone is activated within the range of eight metres, a loud motor-boating sound is heard through the speaker. This is due to a very high RF activity during the activation of the mobile phone. The sound is louder if the mobile phone is within a radius of two metres.

Power to the mobile sniffer is derived from a 12V, 4.5Ah rechargeable battery, as AC power supply may generate audible disturbances in the circuit. A plug-in charger can be used to recharge the battery. Only one power supply with power amplifier is sufficient and the two units can be connected to the power amplifier. Use a good-quality 8-ohm, 6W speaker for LS1. RF reception and performance of the circuit depend on many factors, such as output power of the mobile phone, its orientation and position.

For a Nokia handset, the circuit receives RF signals from a distance of 8 metres and the speaker produces a loud enough warning signal.

More fascinating projects available at electronics projects.

The post Mobile Sniffer appeared first on Electronics For You.

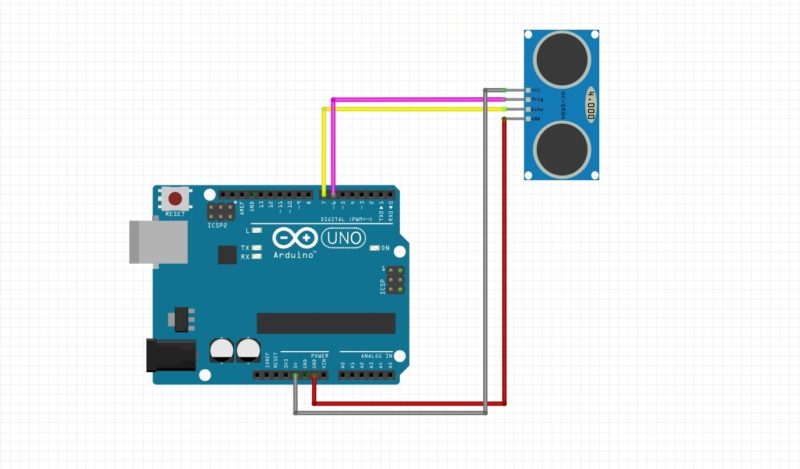

Arduino Board pin 7 – Echo Pin Ultrasonic Sensor

Arduino Board pin 7 – Echo Pin Ultrasonic Sensor

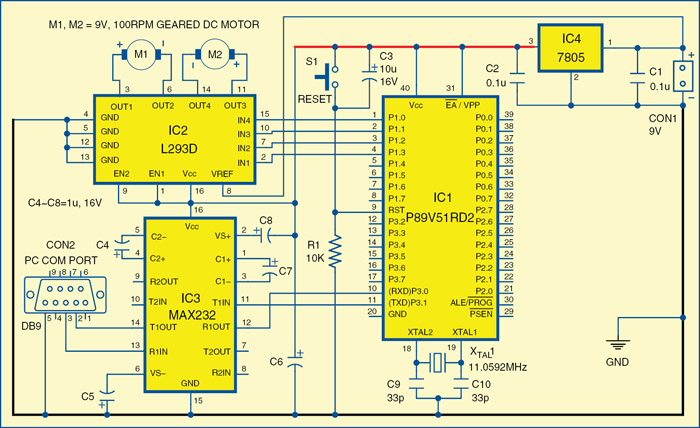

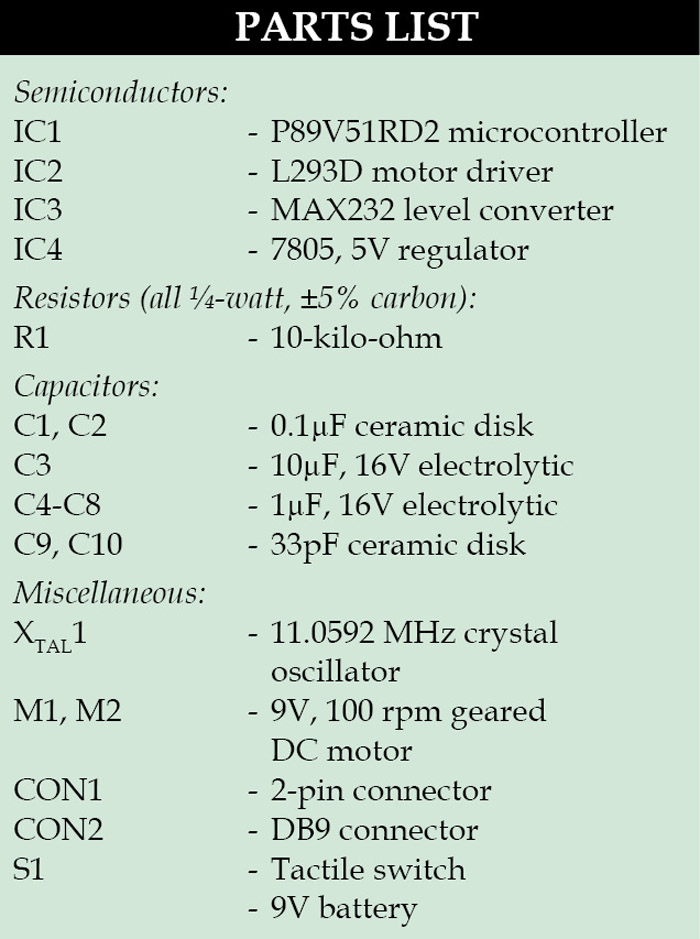

The USB port of the computer is connected to the robot through USB-to-serial converter. Controlling commands to the robot are sent via serial port and the signal levels are converted into 5V TTL/CMOS type by IC3. These signals are directly fed to microcontroller IC1 for controlling motors M1 and M2 to move the robot in all directions. Port pins P1.0 through P1.3 of IC1 are connected to the inputs of IN4 through IN1 of IC2, respectively, to give driving inputs. EN1 and EN2 are connected to Vcc to keep IC2 always enabled.

The USB port of the computer is connected to the robot through USB-to-serial converter. Controlling commands to the robot are sent via serial port and the signal levels are converted into 5V TTL/CMOS type by IC3. These signals are directly fed to microcontroller IC1 for controlling motors M1 and M2 to move the robot in all directions. Port pins P1.0 through P1.3 of IC1 are connected to the inputs of IN4 through IN1 of IC2, respectively, to give driving inputs. EN1 and EN2 are connected to Vcc to keep IC2 always enabled.

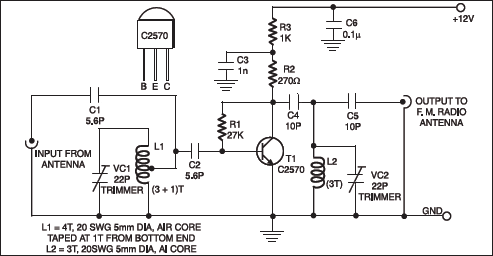

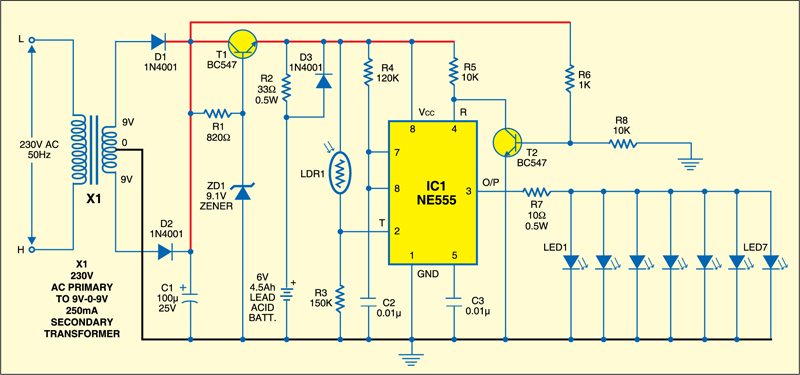

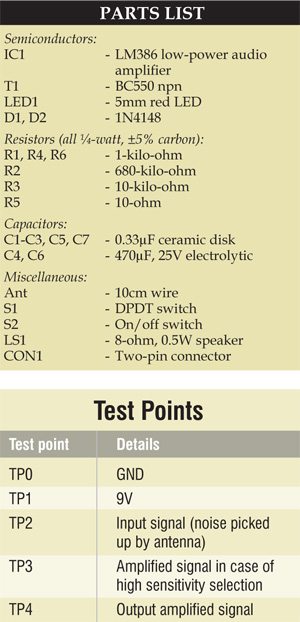

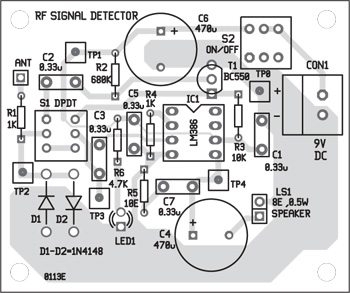

This simple RF signal detector circuit can be used to trace the presence of RF signals and electromagnetic noise in your residential area, office or shop. It can be a useful tool while testing or designing RF circuits. It can also be used to detect electrical noise in your premises.

This simple RF signal detector circuit can be used to trace the presence of RF signals and electromagnetic noise in your residential area, office or shop. It can be a useful tool while testing or designing RF circuits. It can also be used to detect electrical noise in your premises.

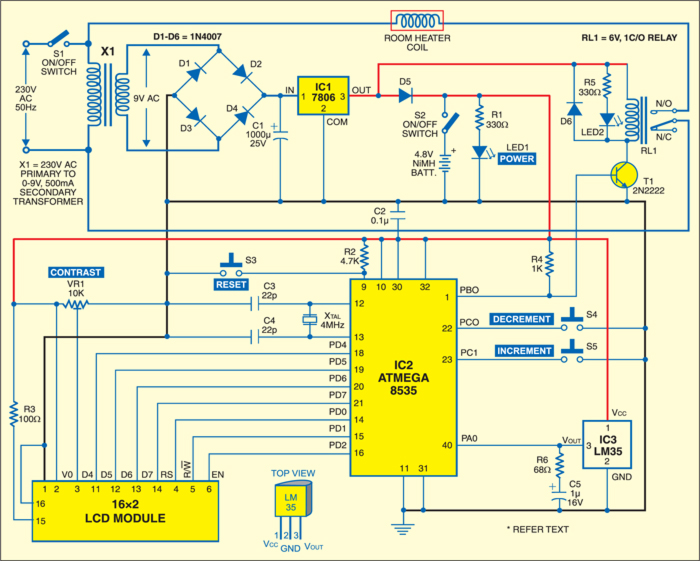

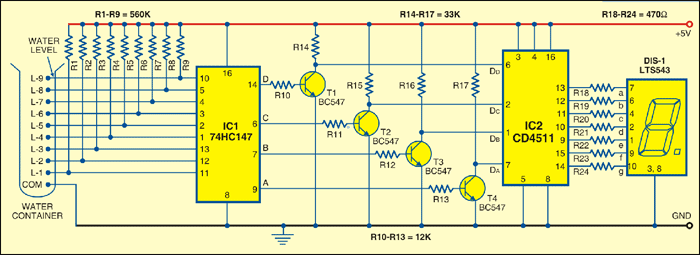

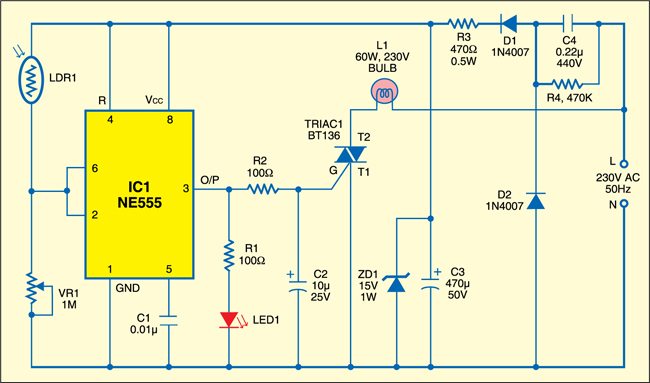

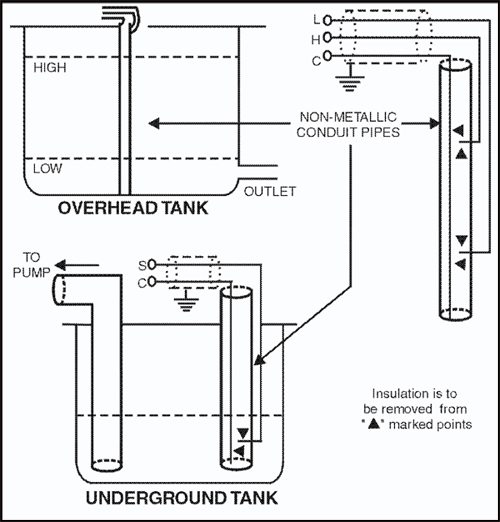

Municipal corporations in many cities supply water during early morning hours. So, you have to wake up early, just to switch on your motor pump and wait till your water tank is filled up. Further, there is no control for overflow of the tank. Many times you come to know of your overflowing tank only when your neighbor informs you. This water pump motor controller can com in handy in these cases.

Municipal corporations in many cities supply water during early morning hours. So, you have to wake up early, just to switch on your motor pump and wait till your water tank is filled up. Further, there is no control for overflow of the tank. Many times you come to know of your overflowing tank only when your neighbor informs you. This water pump motor controller can com in handy in these cases.